Compared to Conventional Plural Component Spray Trucks

Versacoat Requires Up to 50% less man power

VersaCoat system is light weight and compact design can easily be transported by a half ton truck. Accessibility to remote locations, 90 degree spray tip available to access difficult spray locations, quicker to heat to spray time to name only a few advantages out of many.

Save Time + Resources

- Up to 50% less manpower and product required for Versa Coat system compared to a conventional plural component spray trucks, no thinner flushing required.

- Excellent for below ground structural steel and other difficult shapes because of the moderate spray pressure and the continuous on/off finesse spraying capability of the system.

- Minimal training required for VersaCoat vs Conventional Plural Systems. (ie 2 days vs. months).

- Quicker to heat to spray time than conventional units (4 minutes vs. 4 – 6 hours).

- Excellent for residential applications such as spraying pool liners as it does not exceed bylaw noise levels.

- Quickly change products with no additional cost to do so.

- Considerably less maintenance and downtime compared to conventional mobile systems – no high pressure pumps and valves to maintain.

Environmental + Mobile

- Less environmental impact: small foot print, less noise, less pollutants, low operating cost. Accessibility to remote scopes – Helicopter and Skiable.

- Light weight and compact design can easily be transported by a half ton truck.

Beacon remote control and monitoring: GPS traceable control and monitor heat system from anywhere via internet. - Perfect for site work where multiple field welds are made available to blast and spray on a daily basis.

- Can be used to operate conventional and airless spray systems for above ground coatings and internal piping, concrete etc.

- 90 degree spray tip available to access difficult spray locations – less site excavation under the pipe required to access welds.

- Feed hose lengths up to 250’ – 300’ for projects in downtown big cities where street space is a premium.

- Capable of small abrasive blast touch ups.

Pipeline Blasting & Coating Increase Production and Reduce Costs

Mobilize Blast & Coat one 48" Tee Assembly c/ 1.5 m pups

- 2 man crew, 1 crew truck, skid blast unit and VersaCoat system.

- QC equipment

- 3 days in total to mobilze to site, blast & coat, finalize QA, do final QC and travel home.

- Total cost savings to customer using VersaCoat vs. Traditional Plural Component Spray Truck is 42.3%

On-Site Blast & Coat one 48" Tee Assembly c/w 1.5 m pups

- 2 man crew, 1 crew truck, skid blast unit and VersaCoat system.

- QC equipment

- 2 days in total to on-site assembly, blast & coat, QA, complete and do QC.

- Total cost savings to customer using VersaCoat vs. Traditional Plural Component Spray Truck is 38.2%

Compared to Traditional Plural Component Spray Truck

- 3 man crew, 1 crew truck and skid blast unit, 1 Plural Component Spray Truck.

- QC equipment.

- 3 days plus for travel to and from site, assemble, blast & coat, complete QA, do final QC and travel home.

VersaCoat in the Field

Time and cost saving compared to traditional Component Plural Spray Trucks.

VersaCoat System

Application Specifications

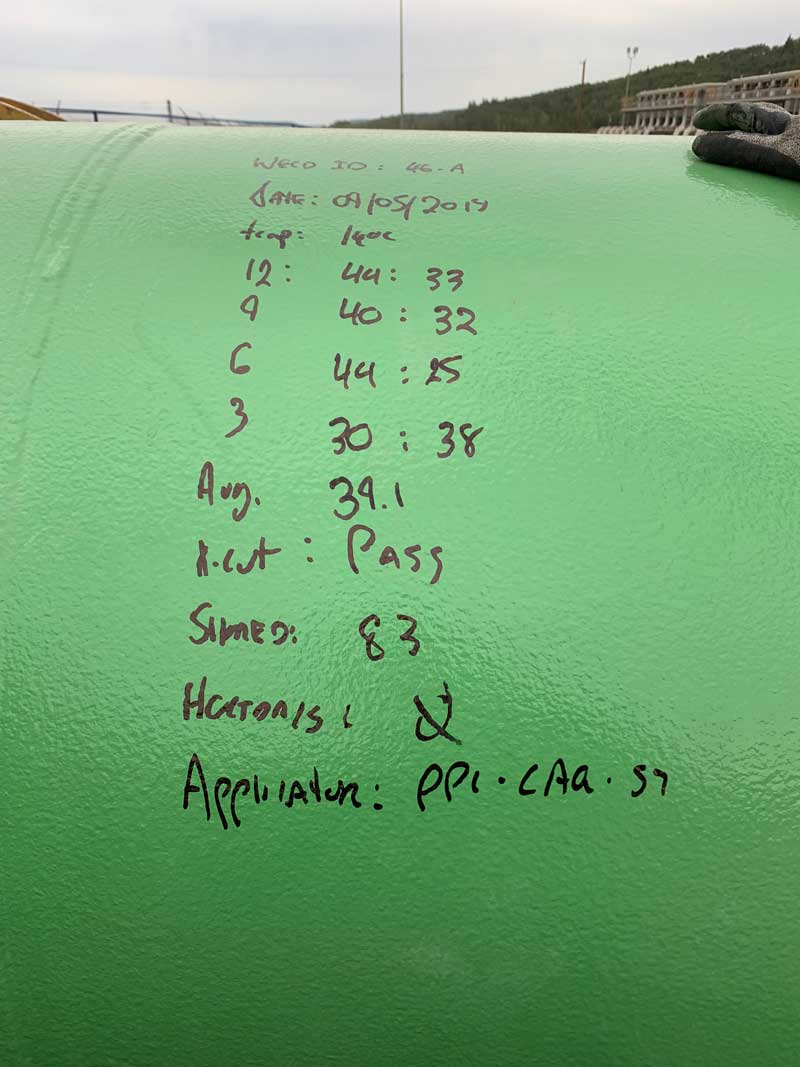

AVERAGE COATING THICKNESSES: 39.1

MILS, X-CUT: PASSED

SIGNED OFF: INSPECTOR 83

HOLIDAYS: 0

PPC APPLICATOR IDENTIFICATION: PPC CAa 57

Bare 48″ Tee Assembly

Coated 48″ Tee Assembly

VersaCoat Spray Coating Application Specs

VersaCoat

(780) 461-7719

809 – 77 ave

Edmonton, AB T6P 1S9

Hours

Mon:7:30 am – 4:30 pm

Tue: 7:30 am – 4:30 pm

Wed: 7:30 am – 4:30 pm

Thur: 7:30 am – 4:30 pm

Fri: 7:30 am – 4:30 pm

Sat – Sun: Closed